Table of Contents

Abstract

Digital Twin Technology (DTT) is revolutionizing the way businesses develop, test, and manage products. By creating a virtual replica of physical products, processes, or systems, organizations can optimize performance, reduce costs, and enhance innovation. This whitepaper explores the concept of digital twins, their benefits, and their applications in product management.

Introduction to Digital Twin Technology

A Digital Twin is a real-time digital counterpart of a physical object or system. It integrates Internet of Things (IoT) sensors, Artificial Intelligence (AI), and data analytics to simulate, monitor, and predict the behaviour of its physical counterpart. This technology enables businesses to gain insights into product performance, detect potential issues, and improve efficiency.

Key Components of Digital Twin Technology:

- Physical Asset or System – The actual product or process being mirrored.

- Digital Model – A virtual representation that mimics the behavior of the physical asset.

- Data Integration Layer – IoT-enabled sensors collect real-time data from the physical asset.

- Analytics and AI – Machine learning and data analytics provide actionable insights.

- User Interface – Dashboards and visualization tools enable interaction with the digital twin.

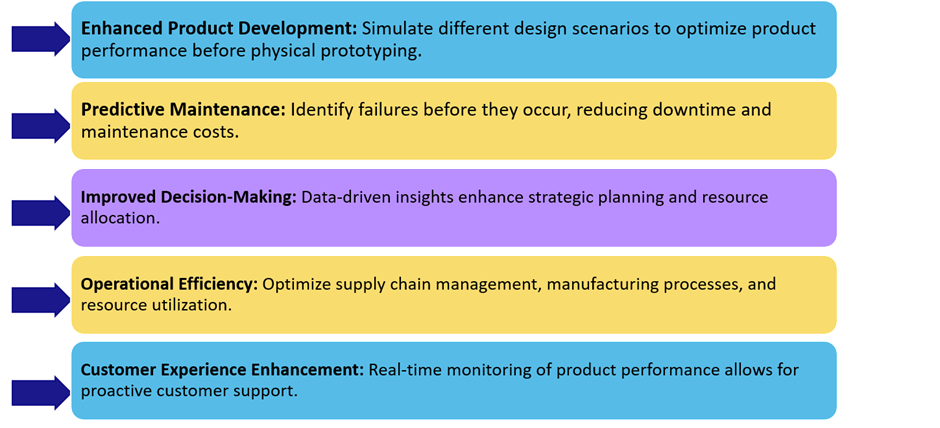

Benefits of Digital Twin Technology:

- Enhanced Product Development: Simulate different design scenarios to optimize product performance before physical prototyping.

- Predictive Maintenance: Identify failures before they occur, reducing downtime and maintenance costs.

- Improved Decision-Making: Data-driven insights enhance strategic planning and resource allocation.

- Operational Efficiency: Optimize supply chain management, manufacturing processes, and resource utilization.

- Customer Experience Enhancement: Real-time monitoring of product performance allows for proactive customer support.

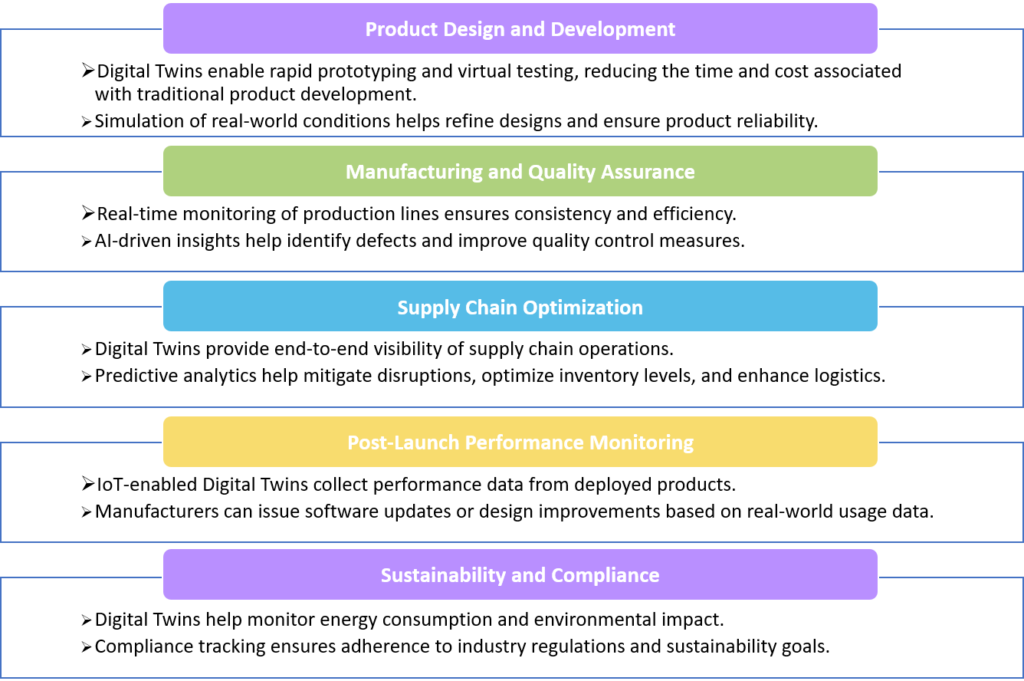

Applications in Product Management:

Product Design and Development

- Digital Twins enable rapid prototyping and virtual testing, reducing the time and cost associated with traditional product development.

- Simulation of real-world conditions helps refine designs and ensure product reliability.

- Manufacturing and Quality Assurance

- Real-time monitoring of production lines ensures consistency and efficiency.

- AI-driven insights help identify defects and improve quality control measures.

- Supply Chain Optimization

- Digital Twins provide end-to-end visibility of supply chain operations.

- Predictive analytics help mitigate disruptions, optimize inventory levels, and enhance logistics.

- Post-Launch Performance Monitoring

- IoT-enabled Digital Twins collect performance data from deployed products.

- Manufacturers can issue software updates or design improvements based on real-world usage data.

- Sustainability and Compliance

- Digital Twins help monitor energy consumption and environmental impact.

- Compliance tracking ensures adherence to industry regulations and sustainability goals.

Case Studies

Automotive Industry: Tesla, BMW, and General Motors (GM)

- Tesla employs Digital Twins to monitor vehicle performance in real-time. Data from embedded sensors is continuously analyzed to detect anomalies, improve efficiency, and enable over-the-air software updates. This ensures that vehicles remain optimized without requiring physical recalls.

- BMW integrates Digital Twin technology into its manufacturing processes, creating digital replicas of production lines. By identifying bottlenecks and optimizing workflows, these simulations enhance assembly line efficiency, leading to cost savings and increased production speed.

- General Motors (GM) uses virtual tests to analyze component behavior under varying conditions, enabling the identification of design flaws, performance optimization, and enhanced safety. Simulating crash scenarios refines vehicle structures while reducing costs associated with physical crash testing. Digital Twins also facilitate real-time vehicle performance monitoring for predictive maintenance, reducing downtime and improving user experience.

Healthcare: Siemens Healthineers and GE Healthcare

- Siemens Healthineers develops patient-specific Digital Twin models for personalized treatment planning. Simulating patient conditions helps doctors predict treatment outcomes and tailor interventions, improving patient care.

- GE Healthcare optimizes the maintenance of medical equipment using Digital Twin models. By analyzing real-time usage data, hospitals can anticipate failures before they occur, reducing downtime and ensuring continuous operation of critical healthcare machinery.

Aerospace Industry: Rolls-Royce

Rolls-Royce utilizes Digital Twins to monitor and maintain aircraft engines. Digital replicas of engines collect real-time data from embedded sensors, capturing critical parameters such as temperature, pressure, and vibration during flight. Analyzing this data allows engineers to predict potential failures and schedule maintenance proactively, reducing operational costs and minimizing aircraft downtime.

Smart Cities: Singapore and Las Vegas

- Singapore has developed a virtual Digital Twin of the entire city, integrating real-time data from traffic, weather, and infrastructure systems. This model assists city planners in simulating urban scenarios, optimizing energy consumption, and improving emergency response strategies.

- Las Vegas leverages Digital Twin technology to enhance public safety, traffic management, and infrastructure planning. Continuous real-world data analysis enables city officials to make informed decisions that improve efficiency and sustainability.

Consumer Electronics: Samsung

Samsung applies Digital Twin technology to enhance product design and customer experience. By creating digital replicas of smartphones and smart TVs, Samsung simulates real-world usage and gathers real-time feedback. This approach helps identify potential issues and optimize designs before mass production. For example, simulations analyze smartphone performance under heavy app usage and extreme temperatures, enabling engineers to refine designs. Digital Twins also facilitate personalized product experiences, improving customer satisfaction and brand loyalty.

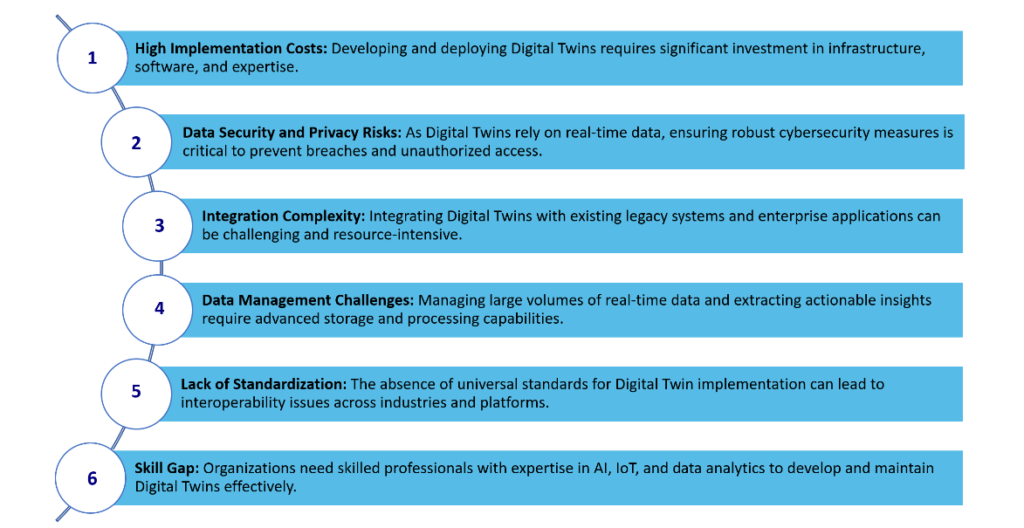

Challenges:

- High Implementation Costs: Developing and deploying Digital Twins requires significant investment in infrastructure, software, and expertise.

- Data Security and Privacy Risks: As Digital Twins rely on real-time data, ensuring robust cybersecurity measures is critical to prevent breaches and unauthorized access.

- Integration Complexity: Integrating Digital Twins with existing legacy systems and enterprise applications can be challenging and resource-intensive.

- Data Management Challenges: Managing large volumes of real-time data and extracting actionable insights require advanced storage and processing capabilities.

- Lack of Standardization: The absence of universal standards for Digital Twin implementation can lead to interoperability issues across industries and platforms.

- Skill Gap: Organizations need skilled professionals with expertise in AI, IoT, and data analytics to develop and maintain Digital Twins effectively.

Conclusion

Digital Twin Technology is a game-changer in product management, enabling businesses to develop smarter, more efficient, and customer-centric products. By integrating real-time data, AI, and IoT, organizations can drive innovation, optimize operations, and enhance product lifecycle management. As technology continues to evolve, Digital Twins will play a pivotal role in shaping the future of product development and management.